IMADE3D

This year I worked for IMADE3D, a 3D printing company specializing in education. Throughout the year I worked on various projects for the owner, Ladi. He has become a mentor of mine. Ladi has an extensive resume in the software industry. He has imparted a countless amount of wisdom on me. From data structuring, scalability, collaboration, coding philosophy, computer science specifics, etc, I’ve learned how applicable these philosophies are to other disciplines. Now in college, I cannot wait to explore.

Projects:

- Prusa slicer

I created custom slicer profiles for the various Jellybox’s to work in the Prusa slicer program. I learned the internals of a 3D printer slicing software and how to develop custom profiles. Throughout the process I also learned about 3D printer operating systems. How gcode from the slicer is turned into commands by the printer’s computer which drive the motors, heating elements, and fans. The code I wrote will be used in the official Jellybox3 Prusa Slicer nozzle settings.

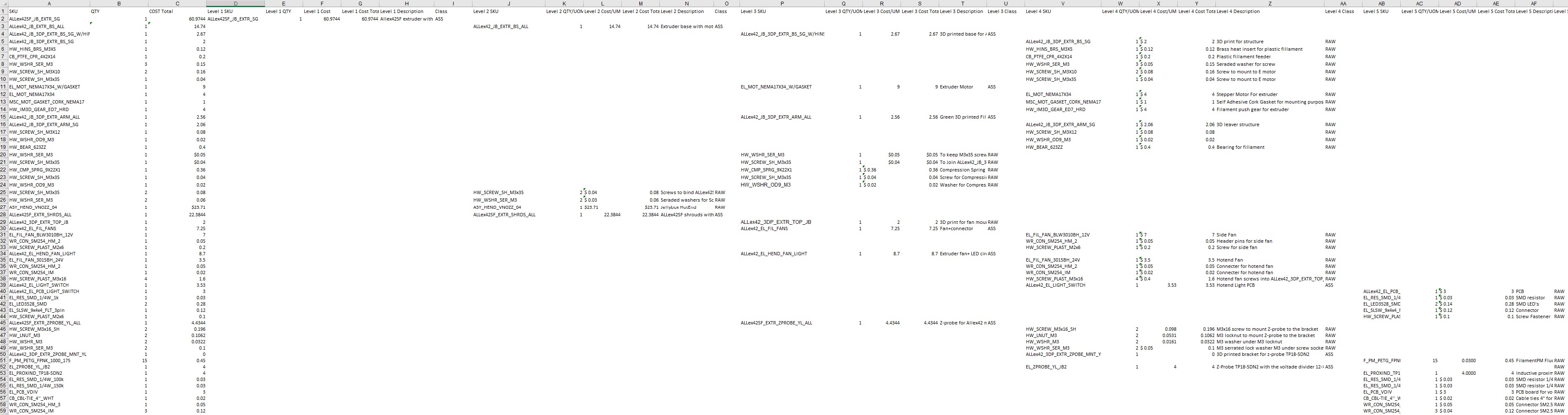

- Jellybox BOM

I was sent a Jellybox, IMADE3D’s printer, and tasked with creating a hierarchy structured bill of materials for its 500 components in excel. I first disassembled and assembled the printer. I then laid out the assembly process of the printer through a hierarchy of raw and assembled items. This consisted of 6 levels of assembly.

Then to understand how to bring a product into reality, I created an inventory management system in excel. It keeps track of current orders, current inventory, which inventory is running low, incoming inventory, descriptions of each item and how they fit into the system, and respective SKU’s.

Below Is a 5 level abstraction for the 3D printers Extruder. A system that is fed plastic, heats it, and lays it on the bed to form the print.

The biggest learning outcomes of this task were more philosophical. How to systematically go about processing and structuring large amounts of data, not repeating yourself, accessing data via a single reference point, and how good structure allows for more efficient collaboration and scalability.

- AIRMON

The goal was to create an air monitor placed in a 3D printing environment to warn users of dangerous air quality.

Throughout the project I learned Python, controlling and reading my computer’s serial port, understanding microcontroller sensor libraries, I2C communication, bit mapping, SD card reading and writing, and more specifics.

Ladi gave me direction and feedback, while I taught myself all of the concepts, programming languages, and had to make it work.

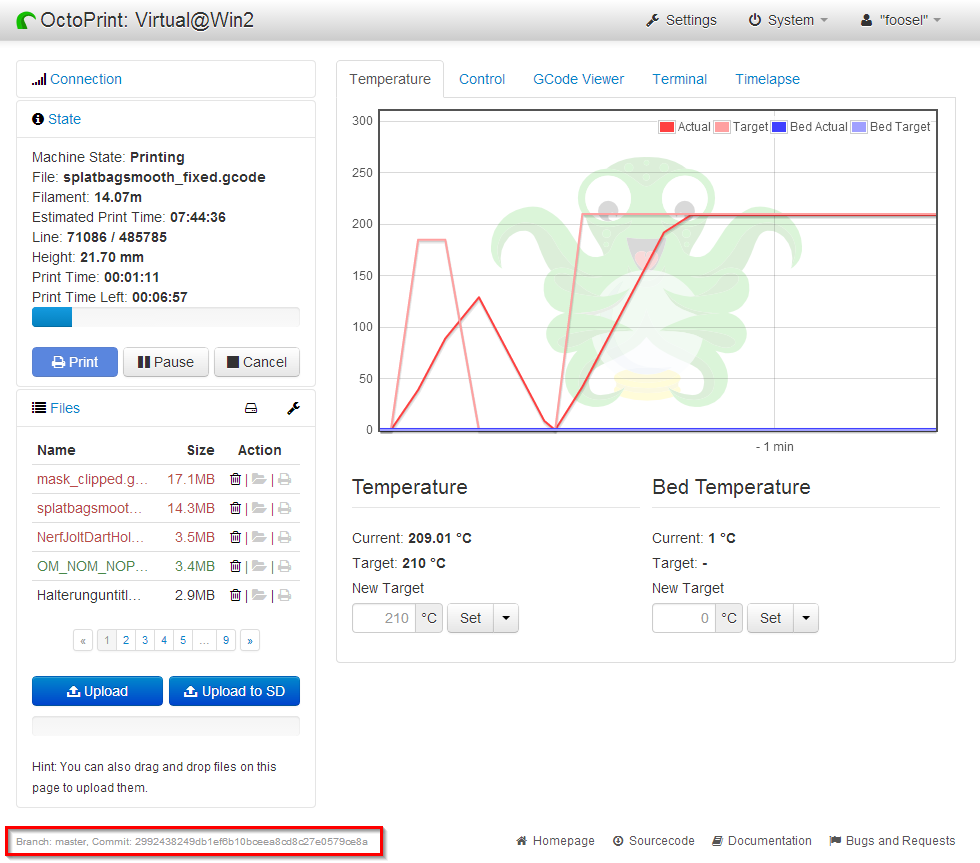

- Octoprint

I implemented Octoprint into my 3D printer via raspberrypi. Through this I was able to control all aspects of my printer through my computer via wifi and mobile phone through a bot. This also allowed me to check in on my printer via video cam anywhere from my phone.